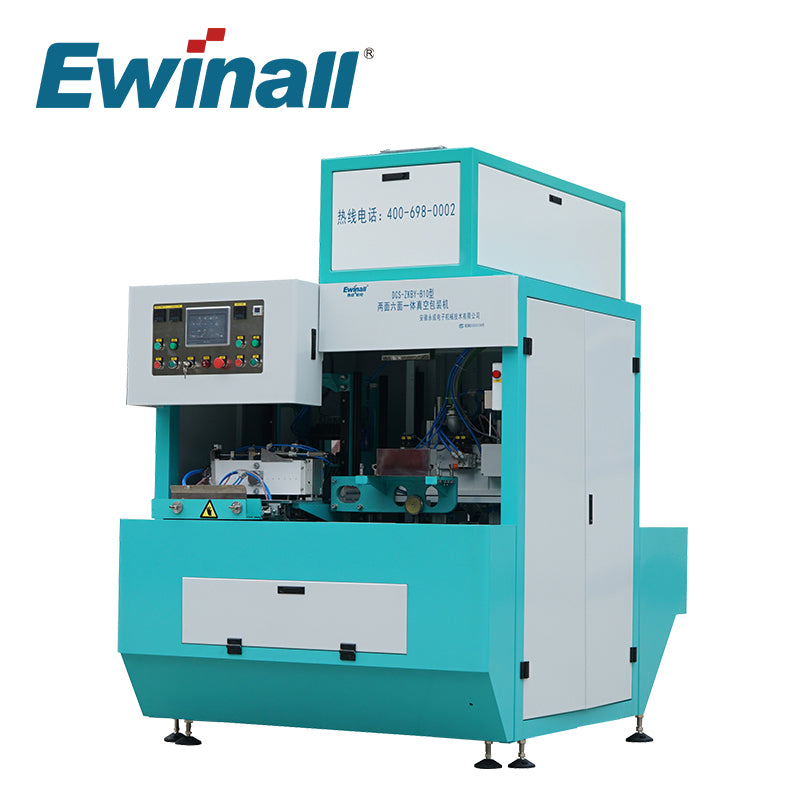

Ewinall DCS-ZKBY-B10 Vacuum Packing Machine Brick & Pillow Shape Rice

Ewinall DCS-ZKBY-B10 Vacuum Packing Machine Brick & Pillow Shape Rice

1. Application

Suitable for quantitative vacuum packaging of granular materials in rice, grains, food and other industries.

2. Features

(1) Advanced two-sided and six-sided shaping integrated design to achieve automatic packaging; metering, shaping, vacuum, sealing, conveying, one machine for two purposes, six-sided and two-sided vacuum packaging at the same time, vacuum equipment with high cost performance.

(2) Unique three-level feeding mechanism, slow feeding with vibration feeding, suitable for a variety of materials, high packaging accuracy.

(3) Small equipment size; small installation space, simple operation and easy maintenance, high work efficiency, and working output of 540 packages/hour.

(4) Unique six-sided shaping device and two-sided pressure shaping device, good shaping effect, low noise; direct vacuuming and sealing at one time, high vacuum success rate, good sealing effect.

(5) Adopting Chinese display touch screen, Siemens programmable controller, intelligent weighing instrument, high-precision alloy steel sensor, Taiwan Aidek pneumatic components, high equipment reliability.

3. Product composition

l Electronic scale mechanism

l Brick Six-sided vacuum shaping mechanism

l Pillow Two-sided vacuum shaping mechanism

l Shaping and sealing mechanism

l Conveying mechanism

l Electric control box

4. Technical Parameters

|

Model |

DCS-ZKBY-B10 |

|

Function |

Pillow Shape, Brick Shape |

|

Packing bag |

Plastic bag (PE composite film bag, anti-leakage, anti-breakage.) |

|

Packing range |

Pillow shape: 1-10kg Brick Shape: 0.25kg~5kg |

|

Packing speed |

180-240 Bags/hour(Pillow) 240-300 Bags/hour(Brick) |

|

Weighing error |

2-5g |

|

Graduation value |

2g |

|

Gas consumption |

0.6Mpa 4m3/h |

|

Power consumption |

AC380V±10%, 50Hz, three-phase five-wire system 3.5KW |

|

Grounding form |

TN-S |

|

Vacuum level |

-0.07-0 MP(adjustable) |

|

Overall dimensions L×W×H |

1535*1935*2248mm |

Standard packaging bag size:

|

|

bag size |

Final product size |

||||

|

Weight(kg) |

Length a(mm) |

Width b(mm) |

Thick e(mm) |

Height A(mm) |

Width B(mm) |

Thick E(mm) |

|

0.5 |

265 |

80 |

50 |

138 |

80 |

50 |

|

1 |

325 |

100 |

60 |

184 |

100 |

60 |

|

2 |

365 |

140 |

75 |

210 |

140 |

75 |

|

2.5 |

390 |

150 |

80 |

230 |

150 |

80 |

|

5 |

485 |

235 |

70 |

335 |

235 |

70 |

Notice:

①Due to the difference in density of different materials, the above standard packaging bag size is based on japonica rice (density 0.92kg/L). If you change to indica rice or other materials, please inform us in time, and the packaging bag size will be adjusted.

②The actual width and thickness of the bag are required to have a negative tolerance, which is generally -2mm (that is, 2mm smaller than the specification size. For example, if the specification is 80mm, the actual size is required to be 78mm~80mm).

③Due to the bag size error, the material density is also different, and the actual final rice package size will be different. Please refer to the actual size.

5. Main configuration

|

No |

Part name |

Brand |

|

1 |

Weighing controller |

GM(China) |

|

2 |

PLC |

Siemens (Germany) |

|

3 |

Load cell |

Zemic (USA) |

|

4 |

Touch screen |

Beijer (Germany) |

|

5 |

Digital vacuum meter |

KITA (Taiwan) |

|

6 |

Temperature Controller |

Omron (Japan) |

|

7 |

Bag clamp switch |

Telemecanique (France) |

|

8 |

Proximity switch |

Telemecanique (France) |

|

9 |

24V DC power Supply |

Mean Well (Taiwan) |

|

10 |

Terminal block |

Phoenix (Germany) |

|

11 |

Switch button |

Schneider (French) |

|

12 |

Solenoid valve |

Airtac(Taiwan) |

|

13 |

Cylinder |

Airtac(Taiwan) |

|

14 |

F R.L. Air Combination |

Airtac(Taiwan) |

|

15 |

Vibration feeding control module |

CUH (China) |

|

16 |

Vacuum Pump |

Rishang(China) |

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share